Thermal Control

The extreme temperatures generated during the combustion of the propellants necessitate the development of a thermal control system, to ensure none of the components of the engine fail. The group was tasked with the development of a system that would cool the engine during all modes of flight.

Two approaches were investigated: the use of high temperature materials, to negate the need for any active cooling; and the use of a regenerative cooling system, in which one of the propellants is passed around the outside of the chamber in order to cool it.

Initial design calculations were carried out in MATLAB, before a parametric combined thermal and structural finite element analysis was conducted in ANSYS.

Ceramics

Very few materials have a melting point high enough to withstand the temperatures produced in a rocket engine. A class of ultra high temperature ceramics under development for use in hypersonic re-entry vehicles was investigated, however it was concluded that in their current state, these materials did not retain enough structural strength at the temperatures required in order to be feasible.

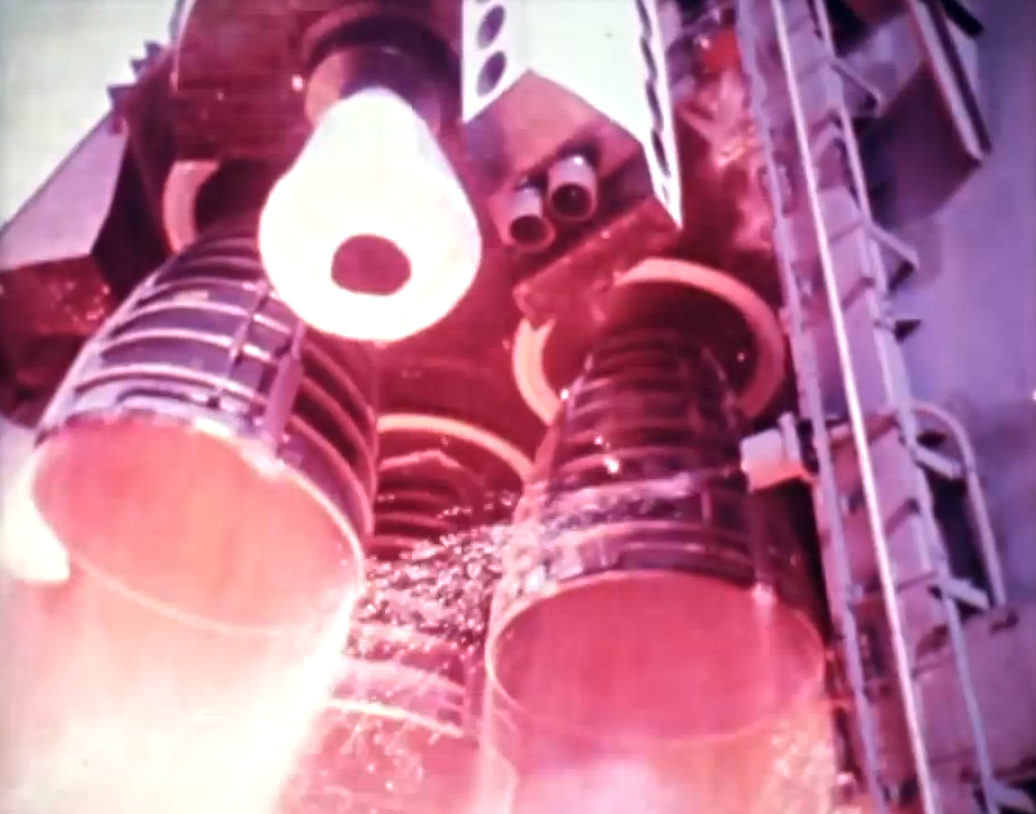

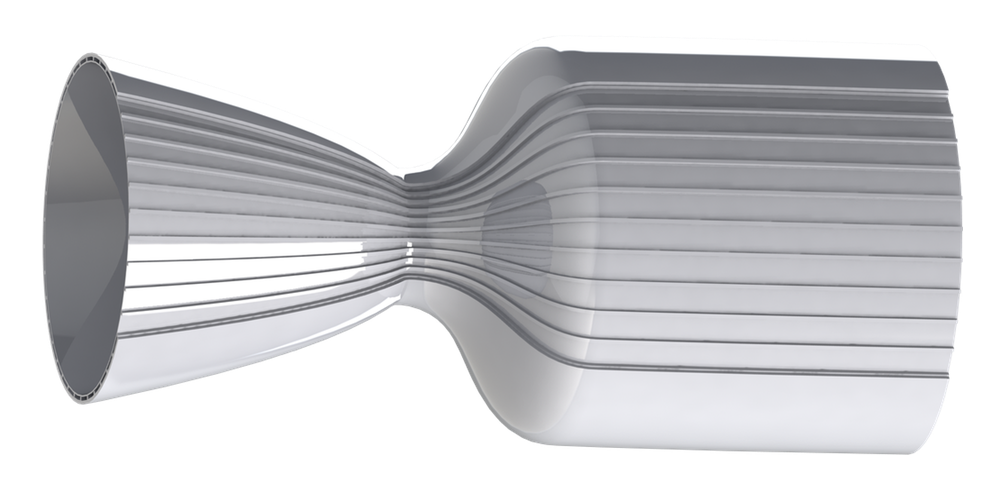

Regenerative Cooling

A customised regenerative cooling system was developed, balancing thermal, structural, and manufacturing limits. Consideration was given to both full-thrust and throttled cases, and the final system was designed to reduce both pressure losses, and system mass.