Injector Plate

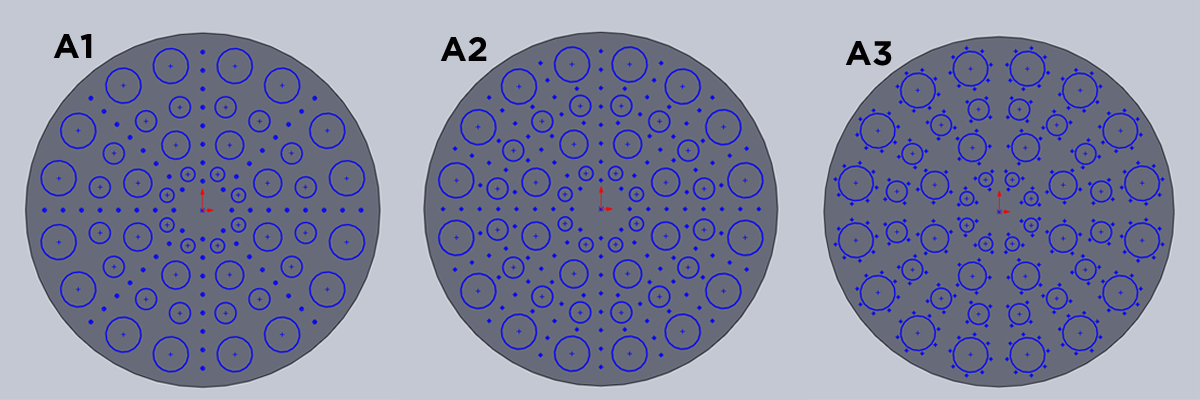

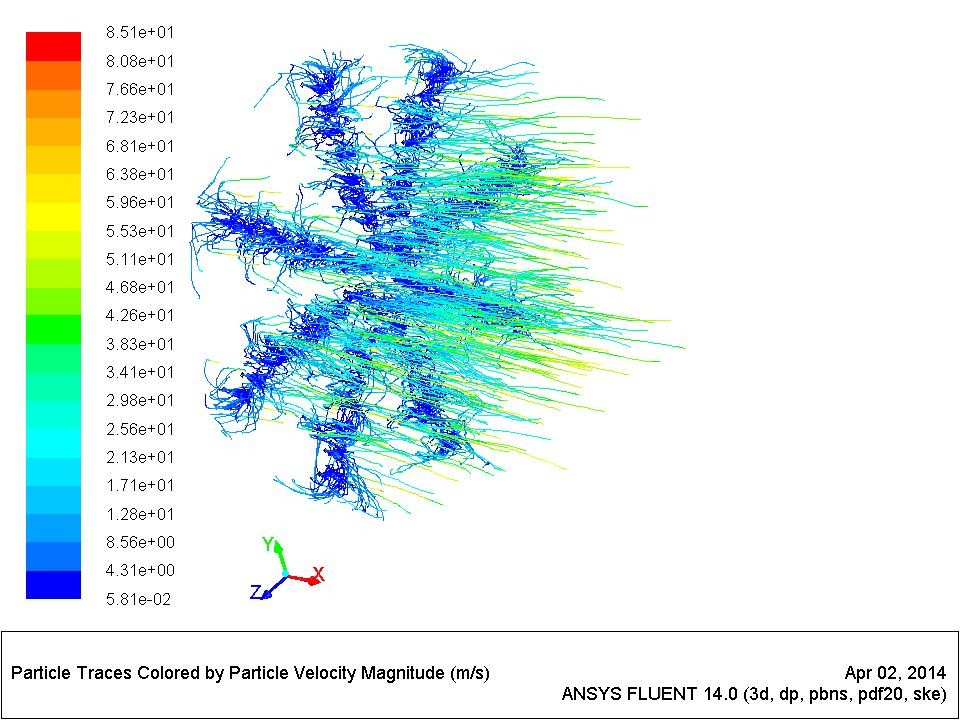

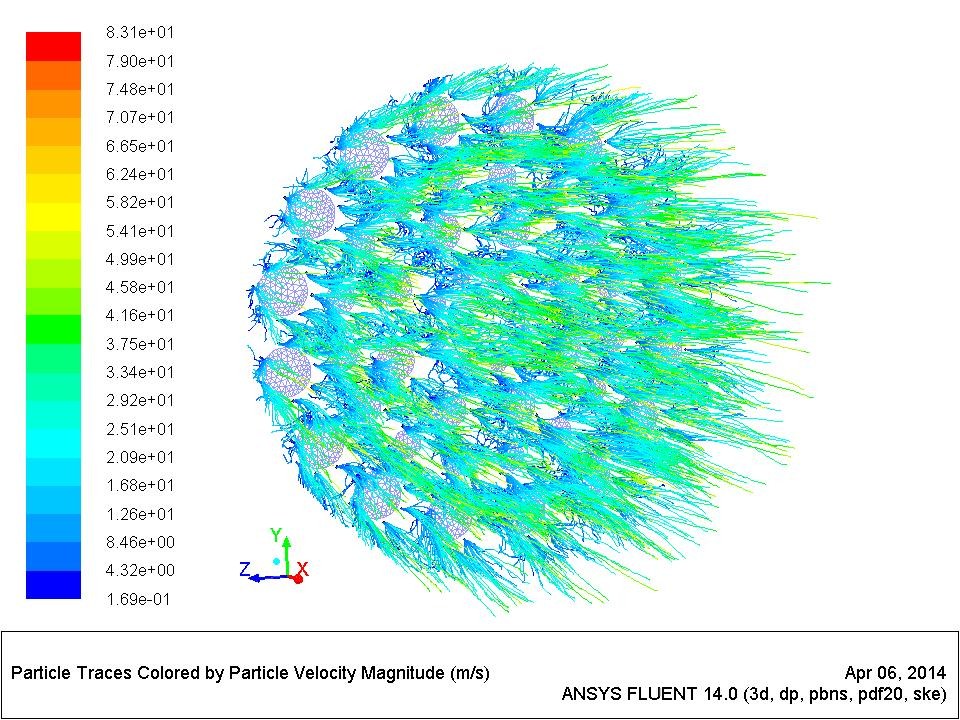

The role of the injector plate is to introduce the two propellants at the top of the chamber to start the combustion process. Effective design of the plate requires knowledge of the flow properties of the propellants, and how they interact with each other within the combustion chamber conditions. Multiple designs were developed and tested in a CFD simulation of the combustion process. This allowed the team to see the effect of changing injector characteristics and to estimate the thrust achieved by each layout.

The structural design of the injector was also investigated by performing analysis to assess the material thickness required to withstand the forces at the top of the chamber. This allowed the mass of the injector plate to be reduced as much as possible while maintaining structural integrity.